Kruzzin5

Well-Known Member

Is there a specific procedure for checking and tightening spokes? I read various methods including every third or fourth spoke. How do you do check without lop-siding the wheel?

That's good to know. Might have to invest in one of the fancy gauges down the road (thought I've put 40,000 km on this one and while I did lose one nipple, it's been solid ever since then).On my 2012 I was using the "ping" method, and it wasn't enough. I lost two spoke nipples, then went about checking the spokes and found none on my rear wheel were close to tight enough, so went slowly tightening them all up going a little on a spoke, skip a few, tighten a little ect until gradually all were tight enough to start torquing, first to a very low value, then gradually going up to the 6nm spec. The wheel was still perfectly fine and true after this. On my 2017 like others have already mentioned, at each oil change just go around the wheel and check for 6nm. Usually 2 or 3 take a bit of adjustment is all on the rear. On the front I've never had a loose spoke on either of my bikes, but still check every 4,000 miles.

This method was recommended to me last year from fellow YST forum member EricV and it worked out perfectly:Is there a specific procedure for checking and tightening spokes? I read various methods including every third or fourth spoke. How do you do check without lop-siding the wheel?

I am not a motorcycle mechanic, just another DIY guy with a fairly broad level of experience. That said, I would first say, do NOT loosen any spokes! You don't want to change tension on the wheel that could cause deformation. Just tighten to torque as needed. that will alter tension by much smaller amounts than if you were to loosen nipples first.

What I do is pick a spot like the valve stem, starting on either side and stick to that side. The spokes alternate directions slightly on each side of the wheel. I put the torque wrench to all the nipples going the same direction on one side, then switch to the opposite side of the wheel, do all the nipples facing one direction there, then back to the first side and do all the nipples facing the other direction, then finish up with the nipples on the second side that were facing the other direction.

This method defaults to checking/tightening alternating spokes due to the pattern of spokes. IMHO, it's a safe way to avoid pulling the wheel out of true and it has worked well for me. Many spokes will be tight. Others may need some tightening to get to torque. With the clicker torque wrench I just put it on and use two fingers to pull the wrench until it clicks. It may click w/o moving the nipple or may go 1/8 to 1/4 turn. When the wheels were new, I was not unusually to get up to a turn, but seldom more than that. Now I occasionally get a little movement on some nipples at 30k miles.

I just watched the video for the Topeak Nano Torqbar and see no reason why that or the Torqbox won't work just fine. A little more precision than required for the moto application, but no harm there. Any 1/4 or 3/8" drive in/lb or Nm torque wrench that covers the range, preferably not at one end of the range, will do the job.

I’ve done the “ping test” and it sounds good. However, now that I’ve read a few articles about spokes coming loose, I have the fear of spoke catastrophe in me! I bought a torque wrench and I’m going to go around to make sure they’re all tight. Just want to make sure I’m doing it in the right sequence. ThanksI don't worry too much about the specific method. Spin the rim, tap the spokes listening for ones that are obviously different sounding, then adjust. Unless your rim is already warped, or you have a tremendous amount of loose spokes, this should not throw anything out of round as long as you do the check during regular intervals.

I think the maximum number I've adjusted was 3 (maybe 4?) and each adjustment was minor. As time has gone one, I found less spokes have needed adjustments.

Having done a lot of mountain and road cycling, I've always checked and sometimes trued my own wheels, so maybe that has helped me be comfortable with it.

That’s the instruction I was looking for! Thank you. I searched the forum but couldn’t find that post, so this is why I posted my thread.This method was recommended to me last year from fellow YST forum member EricV and it worked out perfectly:

So where are you folks buying these fancy torque wrenches ?I check mine at every oil change. I use the (every 4th spoke method) going around the wheel tightening no more than a 1/4 turn and never exceeding the torque of 6 nm.

As my bike had gotten more and more miles I now find very few loose spokes.

There is a difference in tighten and truing which takes a lot more knowledge.

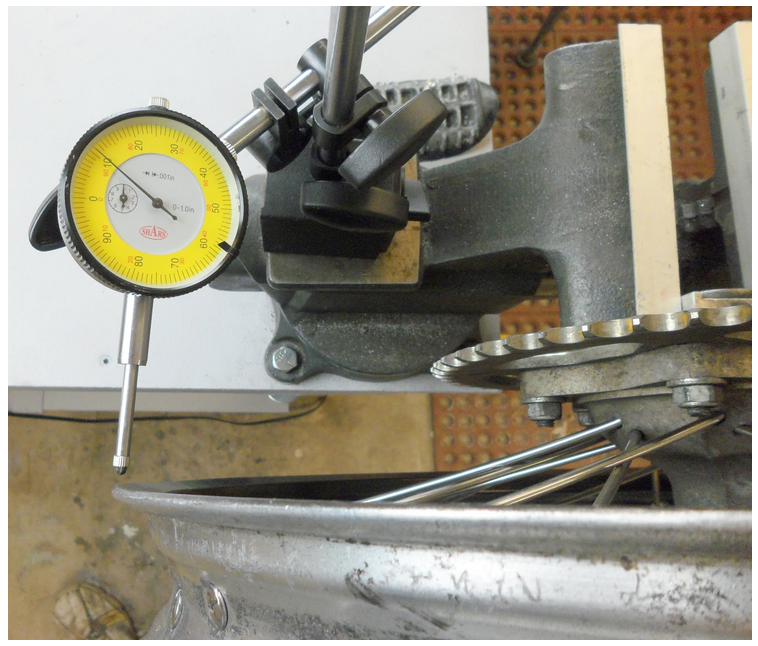

This is the set-up I use.

View attachment 67629

View attachment 67630

I use these and they work great for motorcycle and bicycle spokes as well as delicate, tight areas.So where are you folks buying these

fancy torque wrenches ?

Something to remember, most of us are not torquing the side of the nipple on the flats, but using the 5mm allen on the end of the nipple. Because of our backwards spoke design, with the nipples in the hubs, you can use any 5mm allen wrench or allen socket on a short extension with the torque wrench of your choice. 52 in/lbs or 6Nm, ideally a torque wrench that has that in the middle-ish of it's range, not at one end, or the pre-set styles others have linked to.So where are you folks buying these fancy torque wrenches ?

I just picked up this 1/4" drive, inch pound torque wrench and it works perfectly. As someone suggested, I cut an allen key so that I could fit it between the spokes to make the checks and tightening.So where are you folks buying these fancy torque wrenches ?

On my 2012 I was using the "ping" method, and it wasn't enough. I lost two spoke nipples, then went about checking the spokes and found none on my rear wheel were close to tight enough, so went slowly tightening them all up going a little on a spoke, skip a few, tighten a little ect until gradually all were tight enough to start torquing, first to a very low value, then gradually going up to the 6nm spec. The wheel was still perfectly fine and true after this. On my 2017 like others have already mentioned, at each oil change just go around the wheel and check for 6nm. Usually 2 or 3 take a bit of adjustment is all on the rear. On the front I've never had a loose spoke on either of my bikes, but still check every 4,000 miles.